| Products |

|

| |

| Contact us |

Wuxi Hengye Electric Heater Equipment Co.,Ltd

Add: No.38, Luou Rd., Xituo Area, Hudai Industrial Park, Binhu District, Wuxi

Tel: +86-510-8560 0787

+86-510-8561 3197

Fax: +86-510-8546 3203

Contact:

Mr. Wang +86 17368551515

Mr. Pu +86 18121526918

Mr. Wang +86 18121526921

E-mail: wxhydr@qq.com

httdq@163.net

Web: http://www.hengyecn.cn |

|

|

|

|

| Electric Heating Cables |

|

| High value PTC parallel connection electric heating cables |

Introduction:

The“High value PTC parallel connection electric heating band” also known as alloy PTC parallel connection electric heating band, the patent number is ZL95119695.2, Certificate No.: No. 57856. mainly used in anti-condensing,antifreezing, heat insulation and heat compensation of pipelines,valves,vessels and pipes in the petroleum, chemical, electricity, chemical machinery and all industries.Replace the traditional steam heating, hot water heating.

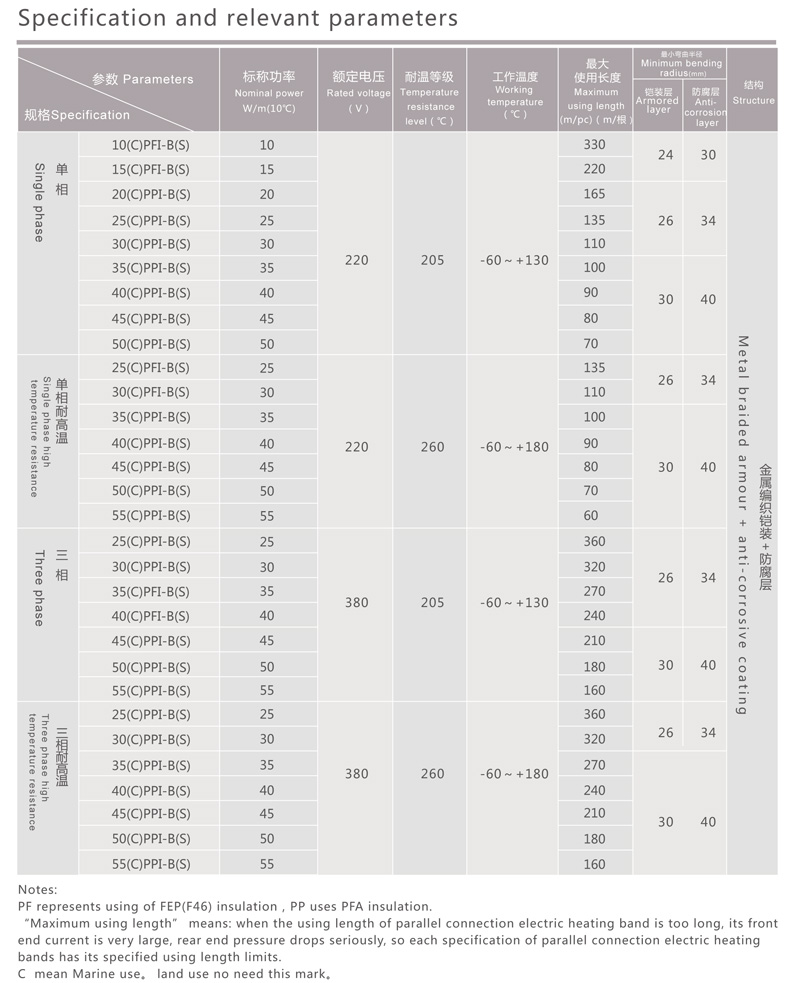

Technical parameters:

◆ Rated voltage: ≤380V 50Hz/60Hz;

◆ Power range: ≤60W/m;

◆ Power error range: ≤±10%;

◆ Dielectric intensity: single phase 1500V/min,triple-phase 1800V/min;

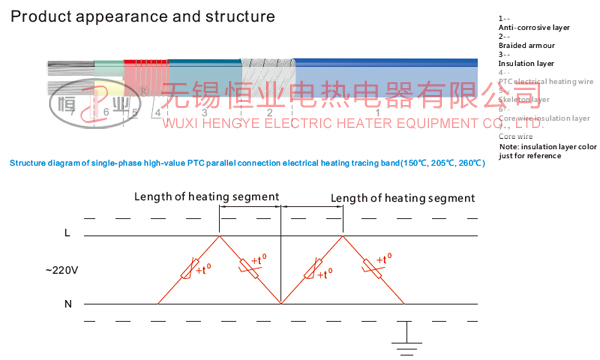

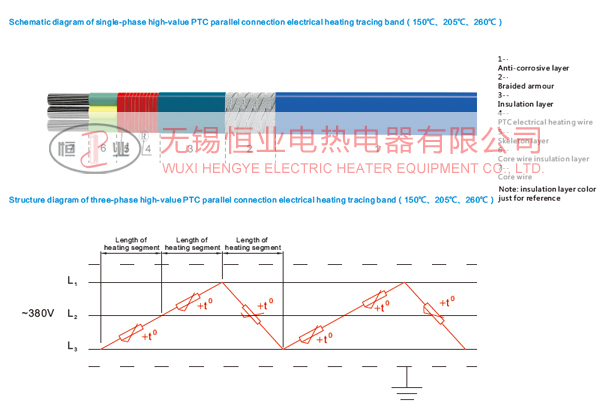

◆ Heating features: PTC power adjustment;

◆ Power adjustment factor: 1.004(△T);

◆ Temperature resistance rating: 150℃、205℃、260℃;

◆ Flame retardant;

◆ Explosion-proof level:ExeⅡT4.

Special features:

So-called“PTC”,it is the abbreviation of English version“Positive Temperature Coefficient”,it is the important area in the international electric heating elements material research.

“Constant resistance type”(also known as the constant power)electric tracing heating apparatus, can not adjust temperature of various locations on the traced body surface, the continuous use will result the electric tracing heating apparatus between the insulation layer and the trace(insulated) bodies burned due to overtemperature on some locations with poor heat dissipation.

Electric tracing heating apparatus with PTC feature,when the temperature rises, its heating elements' own resistance also increases accordingly(heating power is automatically reduced);when the temperature drops, its own resistance accordingly drops(heating power is automatically increased), it is installed and runs between the heat insulation layer and traced(insulated), it can dynamically trace the surface temperature of traced(insulated) bodies, automatically adjusting power of various locations along the length, so that the traced(insulated) parts can maintain a constant temperature, also preventing some parts with poor heat dissipation from burning out due to over-temperature.

Materials with PTC property, not only is the electroluminescent heating elements, but also is a temperature measuring element and power adjustment element.

Introduction of typical PTC materials:

I.PTC alloy(such as nickel, cobalt, chromium, niobium and manganese Ni+Co+Nb+Cr+Mn,iron, nickel Fe+Ni,nickel, cobalt and silicon Ni+Co+Si etc.)

◆ The maximum working temperature is <1000℃(actual working temperature is determined by the temperature resistance rating of insulating materials);

◆ No Curie point, with a wide application range;

◆ PTC feature of the resistance is obvious, it can meet the working requirements of electric tracing heating apparatus;

◆ No power attenuation phenomenon, PTC feature won't be affected by the using time;

◆ Flexible, and bendable;

◆ The impact current during starting is small, switching capacity is small, service life is long.

II.Macromolecule PTC material(conductive composite materials made of polyethylene, polyvinylidene fluoride, and other material incorporated with conductive carbon black)

◆ Temperature resistance ratings are 65℃、85℃、105℃、135℃;

◆ Temperature limiter by Curie point;

◆ PTC feature of the resistance is very obvious;

◆ With the extension of using time, the aging of polymer materials will remove the memory function of the heating elements and the power will reduce;

◆ With a greater starting impact current,affecting the length of usage,if use a large amount of them,it needs a big switching capacity.

III.Ceramic PTC material(conductive composite material made ofbarium titanate ceramic incorporated with rare earth elements)

◆ Temperature resistance rating <250℃;

◆ Temperature limiter by Curie point;

◆ PTC feature of the resistance is very obvious;

◆ Brittle, can not bend;

◆ With the prolong of using time,the heating power will reduce,and effective working life is thousands of hours;

◆ With a greater starting impact peak current,if use a large amount of them,it needs a big switching capacity.Thus, the barium titanate ceramic is brittle, not suitable to be used as heating elements of tracing heating apparatus, the polymer conductive composite materials have power decline and a greater starting impact current and lower temperature resistance level, it also is not the ideal material to make electric tracing heating apparatus. PTC alloy electric heating material has integrated features in many aspects, it is an effective approach and development direction of the high efficiency electric tracing heating apparatus manufacturing.

|

|

|

|